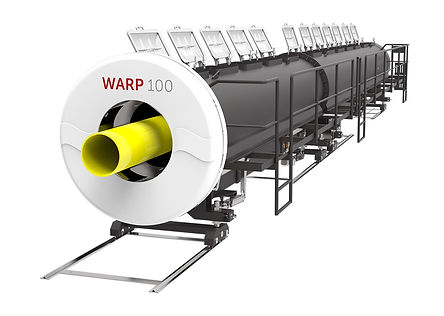

WARP 100

100 % WALL THICKNESS MEASUREMENT FOR GAS AND PRESSURE PIPES

WARP 100 represents a technological quantum leap in pipe measurement. The system is able to comply with the need for higher quality demands in view of product safety, size accuracy, complete proof of quality and a reliable product traceability. WARP 100 inspects 100 % of a pipe wall thickness in both lengthwise and circumferential direction. All of this up to a line speed of 60 m/min.

Measuring accuracy is ± 10 μm1 and measuring results are independent of pipe temperatures.

Together with gravimetric mass throughput control or weight per metre control WARP 100 is able to significantly reduce production costs. A plus in productivity is a plus in profits.

1depending on material types and applicable measuring method

BENEFITS

-

Detailed product information (wall thickness, diameters, eccentricity, ovality)

-

Direct measurement

-

Automatic centering

-

COEX measurement

-

Independent of temperatures

-

Maintenance-free

-

Material savings of 5 % or more through s-min. control or thin points control, improved centering process and a systematic start-up of the extrusion line

-

Documentation for submission to the customer

-

Proven control principles

-

Easy connection to extruder control

-

Easy to use, thus low training needs